Roots Blower Product Description

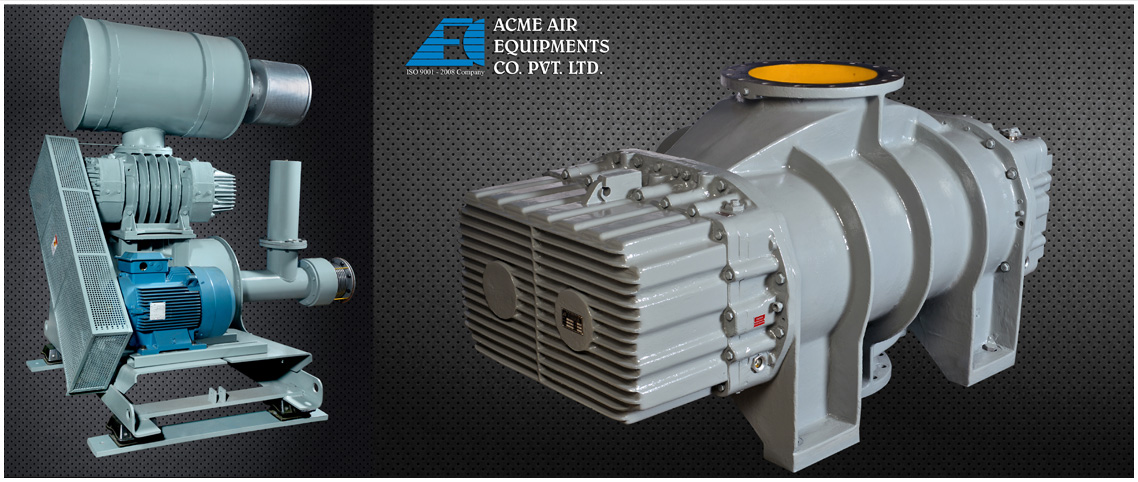

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 quality certified company. It is a most trusted and quality manufacturer of Tri Lobe Roots Blower and allied systems, established in 1990.

Being among the top roots blower manufacturers in India, and across different nations, we offer different types of air blower types, and an advanced design of Tri Lobe Roots Blower which is also called as rotary lobe compressor, rotary piston blower and MVR blower. Basic concepts present in a Twin Lobe Rotary Compressor are modified. The configuration of Rotor is changed to Tri Lobe. This profile enables the rotor pair to entrap and sweep the volume of air/gas 6 times in a revolution in a roots air blower compressor. Effectively this roots blower compressor, delivers higher capacity with smooth flow. The rugged design of Tri Lobe Rotary Compressor with higher rigidity makes it possible to run these lobe compressor machines at higher speed with acceptable vibration level. The roots compressor range covers 5 models from 1000 M3/Hr to 18000 M3/Hr. These are air cooled models. These rotary air blowers are also used for MVR application i.e. Mechanical Vapor Recompression. MVR Blowers are commonly used in vacuum application for Zero Liquid Discharge (ZLD Plant) Plants. ACME as a leading industrial blower manufacturer in Ahmedabad, Gujarat manufacture high quality MVR Blowers keeping in mind the technical requirements and specifications.

Tri Lobe Roots Blowers Application

Rotary blower compressor is used in Kiln firing / charging in cement & steel plants, water treatment systems, aeration, filter backwash, pneumatic conveying, process industries, Mechanical Vapor Recompression (MVR), central vacuum system for paper processing and in general to tackle environmental pollution.These are state of the art MVR blowers involving two rotors (impellers) having tri-lobe configuration. This results into symmetric design imparting extremely high degree of stability and rigidity during high speed running of root blower compressor. This feature makes this rotary lobe air compressor design an ideal choice for smooth and vibration free running. This roots compressor air blower pump high speed running results into higher volumetric efficiency.

Key Attributes: Tri Lobe Rotary Compressor

- Low noise

- High volumetric efficiency

- Minimum vibration

- Reduction in size enabling compact layout

- Flow free from fluctuations

Frequently Asked Questions – Tri Lobe Roots Blower

What is a Tri Lobe Roots Blower?

Tri Lobe Roots Blower, also known as a Positive Displacement Blower, is a type of rotary compressor/exhauster that operates on differential pressure and constant volume characteristics. It is designed for high volume-low pressure applications and is commonly used in systems like Sewage Treatment Plants, Effluent Treatment Plants, Waste Water Treatment Plants, Pneumatic Conveying, Coal Injection, Mechanical Vapor Recompression, Ash Handling, Cement Feeding, Dust Collection, Aeration etc. It features a modified design where the twin lobe rotor design is changed to a tri lobe design, allowing for higher capacity in one rotation, smooth flow, and reduced vibration.

What are the key attributes of a Tri Lobe Rotary Compressor?

The key attributes of a Tri Lobe Rotary Compressor include low noise operation, high volumetric efficiency, minimal vibrations, a reduction in size enabling a compact layout, and a flow that is free from fluctuations. These attributes contribute to the compressor's stable and efficient performance.

What are the applications of Tri Lobe Roots Blowers?

Tri Lobe Roots Blowers find applications in various industries, including cement and steel plants for kiln firing and charging, waste water treatment systems, filter backwash, pneumatic conveying, process industries, mechanical vapor recompression (MVR), central vacuum systems for paper processing, and environmental pollution control. Tri lobe blower is also commonly used in boiler application in Thermal Power Plant.

What are MVR Blowers, and how are they used?

MVR Blowers, or Mechanical Vapor Recompression Blowers, are a type of rotary blowers commonly used to handle steam for Zero Liquid Discharge (ZLD) plants. They play a crucial role in the recycling and recompression of vapor, allowing for efficient and environmentally friendly processes. MVR Blowers are designed to meet the technical requirements and specifications of such applications.

What are the technical specifications of MVR Blowers?

MVR Blowers feature a state-of-the-art design with two rotors (impellers) arranged in a twin lobe configuration. Specially designed seals ensure minimum leakage and efficient compression of steam as per process requirement. This symmetric design ensures high stability and rigidity during high-speed operation, minimizing vibrations. The result is a rotary lobe air compressor with high volumetric efficiency, providing smooth and reliable performance.