Roots blowers have been a cornerstone of industrial operations for decades, offering reliable air movement solutions across various applications. Over the years, the technology has evolved significantly, with Twin Lobe Roots Blowers giving way to more advanced Tri Lobe Roots Blowers. This evolution has enhanced efficiency, performance and versatility, making roots blowers an indispensable tool for industries worldwide.

In this article, we will explore the journey of roots blower technology, highlight the differences between twin lobe and tri lobe designs and showcase how Acme Air Equipments has revolutionized the industry with cutting-edge solutions.

What are Roots Blowers?

Roots blowers are positive displacement machines that move air or gas by trapping a specific volume and forcing it through a system. They are widely used in:

- Wastewater treatment

- Pneumatic conveying

- Industrial vacuum applications

- Cement, steel and chemical industries

The evolution of roots blowers has been driven by the need for greater efficiency, lower noise levels and reduced energy consumption. This journey started with the Twin Lobe Roots Blower and has progressed to the Tri Lobe Roots Blower.

Twin Lobe Roots Blowers: The Foundation of Air Movement Technology

The Twin Lobe Roots Blower, often referred to as a twin blower, is a two-lobe machine that operates by trapping air between its rotors and casing, then compressing and displacing it. Here are some key characteristics:- Simplicity in Design

The twin lobe blower features two lobes that rotate in opposite directions, ensuring a smooth and continuous airflow. - Versatility

A Twin lobe air blower is suitable for various applications, from wastewater aeration to pneumatic conveying systems. - Durability

Their robust construction ensures reliable operation in harsh industrial environments.

However, despite their effectiveness, Twin Lobe Blowers may have limitations in terms of efficiency and noise levels. These challenges paved the way for the development of Tri Lobe Roots Blowers.

The Advancements in Tri Lobe Roots Blower Technology

The Tri Lobe Roots Blower represents a significant leap in technology, offering several improvements over its twin lobe counterpart.

Key Features of Tri Lobe Roots Blowers

- Reduced Pulsation

The addition of third lobe minimizes air pulsations, may lead to smoother airflow and reduced noise. - Enhanced Efficiency

Tri lobe designs optimize air compression, may reduce energy consumption and improving overall system efficiency. - Lower Noise Levels

This design may produce less vibration, making tri lobe blowers quieter and more suitable for noise-sensitive environments. - Improved Thermal Performance

A Tri lobe blower dissipates heat more effectively, may enable longer operational cycles without overheating.

Twin Lobe vs. Tri Lobe Roots Blowers: A Comparative Analysis

| Feature | Twin Lobe Roots Blower | Tri Lobe Roots Blower |

|---|---|---|

| Lobe Design | Two lobes | Three lobes |

| Airflow Smoothness | Moderate pulsation | Reduced pulsation for smoother airflow |

| Noise Levels | Higher noise due to pulsation | Quieter operation |

| Energy Efficiency | Requires more energy for the same output | Energy-efficient operation |

| Application Suitability | General industrial use | Ideal for noise-sensitive and high-efficiency operations |

This comparison demonstrates why many industries are now shifting to tri lobe technology, particularly for applications requiring high efficiency and low noise.

The Twin Lobe and Tri Lobe Roots Blowers have specialized applications across various industries, tailored to meet specific operational needs. Below are detailed applications for both types of blowers:

Twin Lobe Blowers:

These blowers are widely used in a range of industries due to their efficiency in handling large volumes of air. Key applications include:

- Pneumatic Conveying of Grains and Powders: Twin lobe blowers are ideal for transporting bulk materials such as grains and powders through pipelines, ensuring a smooth and efficient transfer in industries like food processing and agriculture.

- Aeration in Wastewater Treatment Plants: These blowers provide the required oxygen for aeration tanks, supporting microbial growth that is crucial for the treatment of wastewater.

- Industrial Vacuum Operations: Twin lobe blowers are used in industrial vacuum systems for cleaning, dust extraction and material handling, especially in sectors like manufacturing and pharmaceuticals.

Tri Lobe Blowers:

Tri lobe blowers are preferred in applications that demand high efficiency, low noise and continuous operation. Some specific uses include:

- Noise-Sensitive Environments: Tri lobe blowers are used where low noise levels are essential for maintaining a quiet and conducive environment.

- High-Efficiency Conveying: With their advanced design, tri lobe blowers are highly efficient forconveying systems, ensuring reliable performance in transporting powders, granules and other materials over long distances.

- Applications Requiring Continuous Operation and Minimal Maintenance: Due to their robust design, tri lobe blowers are perfect for systems that need to run 24/7 with minimal downtime. They are commonly used in industries like chemical processing and power plants, where continuous airflow is essential.

Both blowers provide significant advantages in their respective applications, with twin lobe blowers excelling in bulk material handling and tri lobe blowers standing out for their quiet operation and energy efficiency.

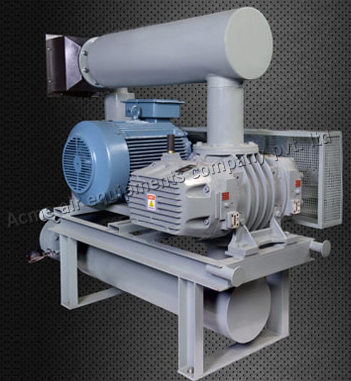

Why Choose Acme Air Equipments for Roots Blowers?

Acme Air Equipments is a leading manufacturer of Twin and Tri Lobe Roots Blowers, offering innovative and reliable solutions tailored to industry needs. Here’s why Acme stands out:

- State-of-the-Art Technology

Acme may integrate advanced engineering to deliver high-performance blowers with superior durability and efficiency. - Customized Solutions

Whether you need a twin lobe or tri lobe blower, Acme provides solutions tailored to your specific requirements. - Comprehensive Support

From consultation to installation and after-sales service, Acme can ensure a seamless experience for its customers.

How to Choose the Right Roots Blower for Your Needs?

Selecting between a twin lobe and tri lobe roots blower depends on several factors:

- Operating Environment

Tri lobe blowers may be more suitable for environments where noise and vibration are concerns. - Budget Considerations

While tri lobe blowers may cost more initially, their energy savings and lower maintenance requirements can offset the investment. - Expert Consultation

Consulting with experts at Acme Air Equipments can help you determine the best solution for your needs.

Conclusion

In conclusion, the advancement from Twin Lobe to Tri Lobe Roots Blowers highlights the industry’s commitment to improving efficiency, performance and sustainability. Acme Air Equipments stands at the forefront of this technological evolution, offering cutting-edge solutions that ensure long-lasting, optimal performance. Partnering with Acme ensures that your systems are equipped to meet future challenges with reliability and innovation.