What is a Pneumatic Conveying System?

A pneumatic conveying system is a material handling solution that utilizes airflow to transport materials through an enclosed pipeline. These systems are widely used for conveying powders, granules, and bulk solids, making them indispensable in industries like food processing, pharmaceuticals, chemicals, and agriculture.

Types of Pneumatic Conveying Systems

Pneumatic systems are classified based on their operational mechanism and the state of materials during transportation:

1. Dilute Phase Conveying

- Operates at high air velocities and low pressures.

- Ideal for lightweight, non-abrasive materials.

- Common in food and pharmaceutical industries.

2. Dense Phase Conveying

- Works at lower air velocities and higher pressures.

- Suitable for abrasive, fragile, or heavy materials.

- Often used in cement, ceramics, and chemical industries.

3. Vacuum Conveying

- Utilizes negative pressure to transport materials.

- Best for short distances or materials that require gentle handling.

4. Positive Pressure Conveying

- Uses compressed air to push materials through pipelines.

- Suitable for long distances and larger material volumes.

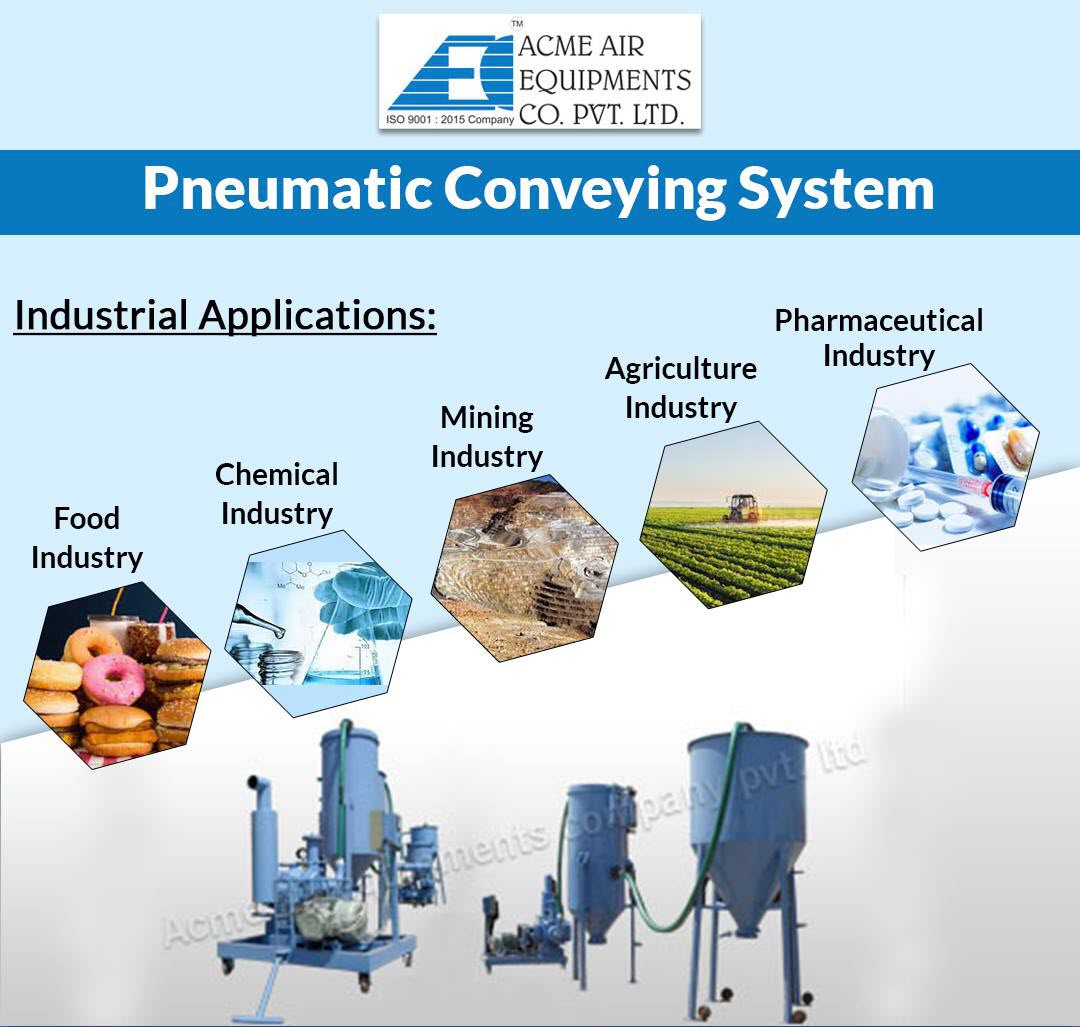

Pneumatic conveying systems are widely used across various industries for transporting bulk materials efficiently and reliably. These systems leverage air pressure to move materials through pipelines, offering a clean, flexible, and low-maintenance solution for industrial applications. While the advantages and basic applications of pneumatic conveying systems are well-documented, this article delves deeper into their unique attributes, types, detailed applications, advantages, and evolving role in modern industries.

A Pneumatic Conveying System is a type of material transport that utilizes air pressure to move bulk materials. The system has multiple advantages and can handle a variety of materials, including bulk solids and liquids. The most important benefit of a pneumatic conveying system is its ability to carry large amounts of material. This type of conveying is ideal for handling almost any powder, but it must be carefully tuned to the material’s characteristics and properties.

Features of Pneumatic Conveying System

The design of a pneumatic conveying system depends on the desired flow rate and distance. The design of the system will depend on the geometry of the materials, including pipe size and line length, the density of the product, and the flow rate of the air mover. It should also detail the type of solid and the characteristics of the material being conveyed. This will make the entire process much simple.

1. Customizable Design

The design of pneumatic conveying systems can be tailored to meet specific industry requirements. Factors such as material density, particle size, distance, and flow rate influence the system’s configuration.

2. Material Compatibility

Pneumatic systems can handle various materials, including:

- Dry Powders: Cement, flour, sugar

- Granular Solids: Plastic pellets, grains

- Sensitive Materials: Pharmaceuticals requiring contamination-free transfer

3. Seamless Integration

Pneumatic conveyors can integrate with existing industrial setups, reducing the need for major structural changes.

4. Flexibility in Layout

The enclosed design of pneumatic systems allows for versatile layouts, including vertical and horizontal routing.

Applications of Pneumatic Conveyor

Pneumatic Conveying Systems can be used in a wide variety of industries and applications. They can be used to transport powdered and dry bulk materials, and they can also be used to sort materials based on density. Aside from being cost-effective, a Pneumatic Conveying System can also assist you to cut labour expenditures while increasing output. In addition to reducing operating costs, a Pneumatic Conveying Systems is highly reliable and easy to maintain.

Pneumatic conveying systems are utilized across diverse industries for numerous applications:

1. Food Processing

- Transporting flour, sugar, spices, and grains in a hygienic and contamination-free manner.

- Ideal for lightweight and fine powders.

2. Pharmaceuticals

- Conveying active ingredients, tablets, and powders while maintaining sterility.

- Minimizes cross-contamination during manufacturing processes.

3. Chemicals

- Handling bulk chemicals, resins, and catalysts.

- Ideal for environments requiring safe and enclosed transport of hazardous materials.

4. Agriculture

- Moving grains, seeds, and fertilizers across silos and processing plants.

- Reduces labor-intensive handling and spillage.

5. Mining and Construction

- Transferring cement, sand, and other abrasive materials.

Dense phase systems are preferred for their durability and efficiency.

Several Advantages of a Pneumatic Conveying System

Comparative Advantages Over Mechanical Conveyors

Pneumatic conveying systems offer several advantages over traditional mechanical conveyors:

- Enclosed Operation: Unlike belt or screw conveyors, pneumatic systems prevent material exposure to the environment.

- Reduced Space Requirement: Pipelines can navigate through tight spaces, offering a more compact solution.

- Scalability: Can handle varying material volumes without extensive reconfiguration.

A Pneumatic Conveying System is an effective means of moving material over long distances. In addition, they are easy to install and use. When choosing a Pneumatic Conveying System, be sure to consider the plant’s physical characteristics and the air supply. A well-designed Pneumatic Conveying System can maximize production and efficiency. So what are the advantages of a Pneumatic Conveying System?

1. Enhanced Efficiency

- Reduced Material Loss: Enclosed systems prevent spillage and contamination.

- High-Speed Transport: Air pressure ensures fast movement of materials.

2. Minimal Maintenance

- Fewer moving parts reduce wear and tear.

- Enclosed design minimizes external contamination and cleaning requirements.

3. Cost-Effectiveness

- Reduces labor costs by automating material handling.

- Long-term savings due to lower maintenance and operational downtime.

4. Environmental and Safety Benefits

- Dust-free operation ensures a cleaner work environment.

- Enclosed systems prevent exposure to hazardous materials.

5. Flexibility

- Easy to adapt to complex layouts and varying operational needs.

- Suitable for a wide range of material types and properties.

The Pneumatic Conveying System has two main advantages. First, it is a cost-effective method of moving materials from one area to another. Since the material is contained within a tube, there is very little risk of material loss. The pneumatic Conveying System is a good option for many types of applications. Its low maintenance requirements and flexible design make it ideal for a variety of environments.

Pneumatic Conveying Systems use air to move materials from one location to another. The air in the pipeline is used to transmit propulsion force to the material. The air flows from one location to another at a constant speed. A pneumatic conveying system can be used to move bulk materials between different locations. In fact, it is more efficient than a conveyor. Its benefits include minimal downtime and increased productivity.

Challenges and Limitations of Pneumatic Conveying Systems

While pneumatic conveying systems offer significant advantages, they also have certain limitations:

1. Energy Consumption

- Air compression or vacuum generation requires significant energy input.

- Energy-efficient designs and controls can mitigate this challenge.

2. Material Limitations

- Not ideal for materials with extremely high densities or irregular shapes.

- Requires precise tuning to prevent material degradation.

3. Initial Investment

- Higher upfront costs compared to some mechanical systems.

- Long-term benefits often outweigh initial expenses.

Emerging Trends in Pneumatic Conveying Systems

1. Automation and Smart Controls

- Integration of IoT and AI technologies for real-time monitoring and predictive maintenance.

- Smart controls optimize energy usage and operational efficiency.

2. Energy-Efficient Designs

- Advanced air movers and regenerative blowers are reducing energy consumption.

- Use of variable frequency drives (VFDs) for adaptive control of air supply.

3. Sustainability Initiatives

- Eco-friendly designs aim to reduce emissions and waste.

Use of renewable energy sources for powering pneumatic systems.

The Bottom Line

A Pneumatic Conveying System works with air to move materials. The system uses gas at different speeds to transport various materials. It can be either lean, dense, or dilute. The gas velocities are higher at the feeding point than elsewhere. In a diluted phase, the air has a low velocity. This allows the material to be transported without damage.