A Pneumatic Conveying System can be categorized into several types: Positive-, Lean-, and Thick-phase. Each has its advantages and disadvantages. Listed below are some of the benefits and features of each type. Read on to learn more about them. Depending on the application, you may need to choose one over the other. Here are some other benefits of a Pneumatic Conveying System.

What is Dilute-phase Pneumatic Conveying System?

A dilute-phase pneumatic material conveying system, or DPCS, has several advantages over a mechanical conveyor. Unlike traditional mechanical conveyors, DPCS(dense phase pneumatic conveying system) is more efficient and has a longer lifespan than mechanical ones. Know how it works and how to choose the right DPCS for your specific application.

A typical dilute-phase pneumatic conveying system picks up conveying air at a speed of three to six feet per minute, and the line pressure reaches a low at the beginning and a high near atmospheric pressure at the end. The particle velocity is crucial to the overall performance of the dense phase conveying system. Too slow or too fast of a velocity can cause the product to degrade or plug a pipeline. If the particle velocity is too high, it can cause the material to foul the walls of the pipe and cause wear.

A dilute-phase pneumatic system can convey almost any type of material. Some common materials include flour, resins, speciality chemicals, and ground feeds. A dilute-phase system is usually less expensive than a dense-phase system, but the pressure differential must be high. It is important to consider the installation location, humidity, and altitude when determining the air volume required for the dilute phase pneumatic conveying or DP system.

What is Positive-phase Pneumatic Conveying System?

A positive-phase pneumatic conveying system works by using a medium-pressure air stream to transport bulk materials. Material particles are held in suspension by the air stream. Usually, the material is fed into the system through a transfer vessel. There are a few advantages to this type of pneumatic conveying system. These include: (1) reduced air consumption; (2) reduced pressure on the material during conveying; and (3) increased product velocity.

A positive-phase pneumatic conveying system is also known as a dilute-phase pneumatic conveying system. In this type of system, the air is pumped through a valve and uses a fan to create air pressure. The material is then removed from the system through a separator. The speed of the positive-phase system is fifteen to thirty-five meters per second. A dilute-phase system requires a pressure vessel and an inlet valve. Conversely, a negative-phase pneumatic conveying system is designed in the reverse and creates a vacuum.

What is Lean-phase Pneumatic Conveying System?

In a wide range of industrial applications, the lean-phase pneumatic conveying system offers several advantages, including process hygiene and routing flexibility. Particle attrition is caused by high impact velocities and requires an account of particle distribution into child particles.

The primary advantage of a lean-phase pneumatic conveying system is its ability to handle materials that are abrasive, but not fragile. Furthermore, these materials are typically light in density (approximately 800kg/m3). Furthermore, they do not deposit on the transport pipe during transport. This makes lean-phase pneumatic conveying systems a practical choice for many applications.

A similar setup to the lean-phase pneumatic conveying system is used for the vacuum-dense phase. Both involve a vacuum pump and a sender hopper for inlet material. In the case of the latter, the sender hopper does not need to be specially constructed. Then, a frequency drive and pressure sensors are required to control the pneumatic system. The target flow rate must be determined beforehand, as will the diameter of the pipe. However, once this is determined, the pipe diameter can be estimated from experience and altered later on in the design process.

What is Thick-phase Pneumatic Conveying System?

For a dense-phase pneumatic material conveying system to work properly, you must know how to calculate and test particle-velocity requirements. A dilute-phase system is not suitable for medium-sized granules, but a small-bore pipe can provide the flexibility to move a powder through a congested plant. To get the best results, you should consider the following parameters:

Dense-phase conveying uses smaller amounts of air at a higher pressure. This helps the materials transfer in slugs, and it also minimizes wear to the conveying pipe. The density of the materials minimizes impact-related damage and extends the life of the system. However, this type of system requires that you have a high-pressure air supply. It should also be noted that the air supply is more complex than the other two types of pneumatic conveying systems.

Dense-phase pneumatic conveying uses low-velocity motive gas to transfer materials. This type of system has less impact and is suitable for transferring most materials. The low-velocity feature makes the system suitable for conveying most materials, and it also prevents product breakage and material segregation, two major factors in the downstream process. A dense-phase pneumatic conveying system is an excellent choice for difficult, friable and mixed batch materials.

Comparison between Different Types of Pneumatic Conveying Systems

|

Type |

Key Strengths |

Limitations |

Best Applications |

|

Dilute-Phase |

High velocity, good for lightweight materials |

Higher air consumption, potential material degradation |

Transporting fine powders, lightweight plastics, or food ingredients over long distances. |

|

Dense-Phase |

Low velocity, minimal material degradation, suitable for abrasive materials |

Requires high-pressure air supply, slower conveying speed |

Moving fragile or abrasive materials like glass beads, ceramics, or friable granules in short to medium distances. |

|

Lean-Phase |

Hygienic, versatile, and suitable for a variety of materials |

May cause particle attrition at high velocities |

Food, pharmaceuticals, and lightweight industrial chemicals. |

|

Thick-Phase |

Gentle on material, efficient use of air, reduced wear on pipes |

Complex air supply system, requires careful material testing |

Transporting mixed batch or delicate materials like plastic resins, recycled materials, or fine powders. |

Innovative Applications of Pneumatic Conveying Systems

Modern pneumatic conveying systems are evolving with technological advancements. Below are some innovative applications that demonstrate their versatility:

- Smart Pneumatic Conveying Systems:

Integration of IoT technology enables real-time monitoring and control. Sensors can track material flow, pressure, and temperature, ensuring optimal system performance and reducing downtime. - Energy-Efficient Pneumatic Conveyors:

Modern designs now feature energy-efficient blowers and optimized pipe routing to reduce energy consumption. These systems are particularly beneficial in industries where sustainability is a priority. - Multi-Material Handling Capabilities:

Advanced systems are designed to handle multiple materials within a single setup, switching between product streams seamlessly. This is particularly useful in sectors such as food and beverage or multi-product manufacturing facilities.

Emerging Trends in Pneumatic Conveying Systems

Adding a section on trends could highlight how the technology is adapting to meet modern industrial demands:

- Focus on Sustainability:

Pneumatic conveying systems are increasingly being tailored to support eco-friendly operations. For instance, systems handling biodegradable materials or reducing energy consumption are becoming more prevalent. - Customized Conveying Systems for Unique Materials:

Industries dealing with specialized materials, like pharmaceutical-grade powders or high-value plastics, are leveraging highly customized pneumatic systems. These designs account for material-specific characteristics like flowability, temperature sensitivity, and particle size. - Compact and Modular Designs:

To save space in modern manufacturing facilities, compact and modular pneumatic conveying systems are being developed. These are easy to install and integrate with existing equipment.

Maintenance Considerations for Long-Term Performance

Adding a brief section on maintenance can give readers practical advice for ensuring their systems perform efficiently:

- Regular Inspections:

Conducting routine checks on pipe fittings, valves, and blowers can help identify wear and tear early, reducing the risk of downtime. - Cleaning Protocols:

Industries like food and pharmaceuticals can benefit from clean-in-place (CIP) systems, which allow for thorough cleaning without disassembly. - Lubrication and Component Replacement:

Ensuring that moving parts are adequately lubricated and replacing worn components in a timely manner extends the lifespan of the system.

In Conclusion

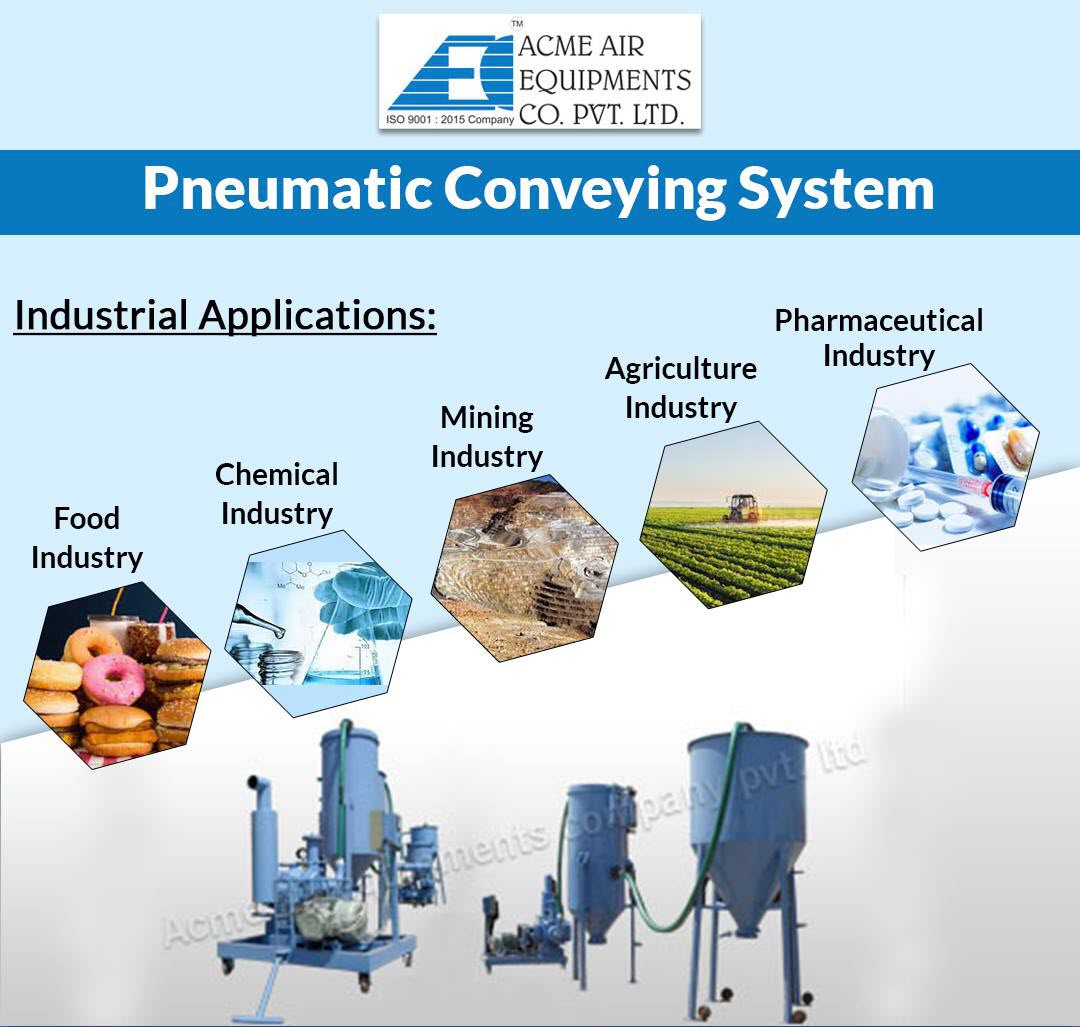

When compared to other methods, pneumatic conveying is an effective way to handle and move different kinds of high volume granulated and powdered products with less waste and at a reduced price. Across a wide number of sectors, pneumatic conveying may be used to move a number of choices, including chemicals, food and drink, and much more. No matter how complicated your operation is or what kind of commodity you are transporting, pneumatic conveying can identify and resolve your most difficult problems and create custom engineering solutions that are effective.