A liquid ring vacuum pump is a type of positive displacement, rotating pump. It can be a single stage or two-stage pump. In this article, we will discuss how these pumps work and what their limitations are. We will also explore their advantages and disadvantages. Read on to learn more about liquid ring vacuum pumps. You’ll be able to choose the best one for your application! There are many different types available on the market.

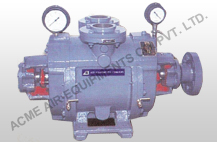

Closed Circuit Liquid Ring Vacuum Pump

A closed-circuit liquid ring vacuum pump is a simple pump with a rotor chamber and a series of overlapping, shaped rotor blades. The liquid that enters the pump is a compatible fluid, such as ethylene glycol, mineral oil, or other organic solvent. These liquids can be added or removed from the system, and the basic principle is the same. The following are some tips for installing liquid-ring vacuum pumps:

A liquid ring vacuum pump uses a circulating liquid to extract high-quality liquid at low pressures. These pumps are highly efficient at removing water, oil, or other media. A closed-circuit liquid ring vacuum pump is suitable for a variety of applications, including moisture extraction, vacuum distillation, condensation, and mineral beneficiation. It can be fitted with a check valve to prevent back flow.

Before installing a pump, be sure to remove any protective coverings and clean all exposed parts. The pipework should also be clear of debris and foreign objects before connection. Always connect a pump to a pipe after it has been sealed with liquid. If a pump has not been sealed with liquid yet, it is time to install the sealing system. For best results, run the pump with the liquid inside. And remember do not use a pump that leaks.

Two-stage Liquid Ring Vacuum Pump

A two-stage liquid ring vacuum pump works on the same principle as a single-stage pump. A liquid ring forms on the inner chamber wall, which is filled with water between the blades. The water flows in and out of the pump in a periodic reciprocating motion, and a fixed suction and exhaust port completes the suction process. The two-stage pump helps to reduce the exhaust pressure of the first stage while improving the vacuum produced by the first.

A two-stage liquid ring pump is highly efficient and is highly reliable. The liquid ring technology in these pumps makes them suitable for many different types of fluids and gases, including explosive gas. This pump is typically composed of durable materials and is ideal for many different types of process vacuum applications. Some types of liquid ring vacuum pumps can even be used to pump explosive gasses. Whether you are looking for an industrial vacuum pump for a chemical plant or a pharmaceutical facility, liquid ring pumps are highly durable and have long lifespans.

A two-stage liquid ring vacuum pump is made of two stages. The first stage has a hub, where the impeller is attached. The blades are offset from the center and sit between end plates with shaped holes. The second stage has a discharge port, which enables you to achieve a deeper vacuum. Ultimately, you will save about 50% of operating fluid by using this pump. This pump type has many benefits over its single-stage counterpart.

The Bottom Line

Liquid ring vacuum pumps come in larger sizes, which makes them ideal for applications requiring high vacuum levels. Furthermore, they do not require multiple pumps. Also, it is a versatile pump that can handle flammable and potentially toxic gas. However, to choose the right pump for the application, you should check out the capacity correction factors in the pump selection diagram. Once you’ve chosen the right pump for your application, the next step is to evaluate its performance.