Table of Contents

In today’s competitive industrial landscape, maintaining high product quality is paramount. One critical aspect that can significantly impact product quality is the material handling process. Contamination during material handling can lead to defective products, which not only affects the reputation of the manufacturer but also leads to financial losses. This is where pneumatic conveying systems come into play. These systems offer a contamination-free solution for transporting materials, thereby ensuring high product quality. In this article, we will explore the various aspects of pneumatic conveying systems, their applications, and how they contribute to improving product quality.

Understanding Pneumatic Conveying Systems

What is a Pneumatic Conveyor?

A pneumatic conveyor is a system that uses air pressure or vacuum to transport bulk materials through a pipeline from one location to another. This method of material handling is widely used in industries such as food processing, pharmaceuticals, chemicals, and manufacturing, where contamination-free transport is crucial.

Pneumatic Conveyor Working Principle

The working principle of a pneumatic conveyor involves the movement of materials through a closed system of pipelines using a stream of air.

The materials are introduced into the pipeline at one end, carried by the air stream, and then separated from the air at the destination point. This process can be accomplished using either pressure-driven or vacuum-driven systems.

Types of Pneumatic Conveying Systems

Dense Phase Pneumatic Conveying System

Dense phase pneumatic conveying systems transport materials at low velocities and high pressure. This type of system is ideal for handling abrasive or fragile materials because it minimises wear and tear on the equipment and reduces material degradation. Dense phase systems are often used in applications where product quality and integrity are critical.

Lean Phase Pneumatic Conveying System

Lean phase pneumatic conveying systems, also known as dilute phase systems, transport materials at high velocities and low pressure. These systems are suitable for conveying non-abrasive, light materials over long distances. Lean phase systems are commonly used in applications where high throughput is required, but the risk of material degradation is lower.

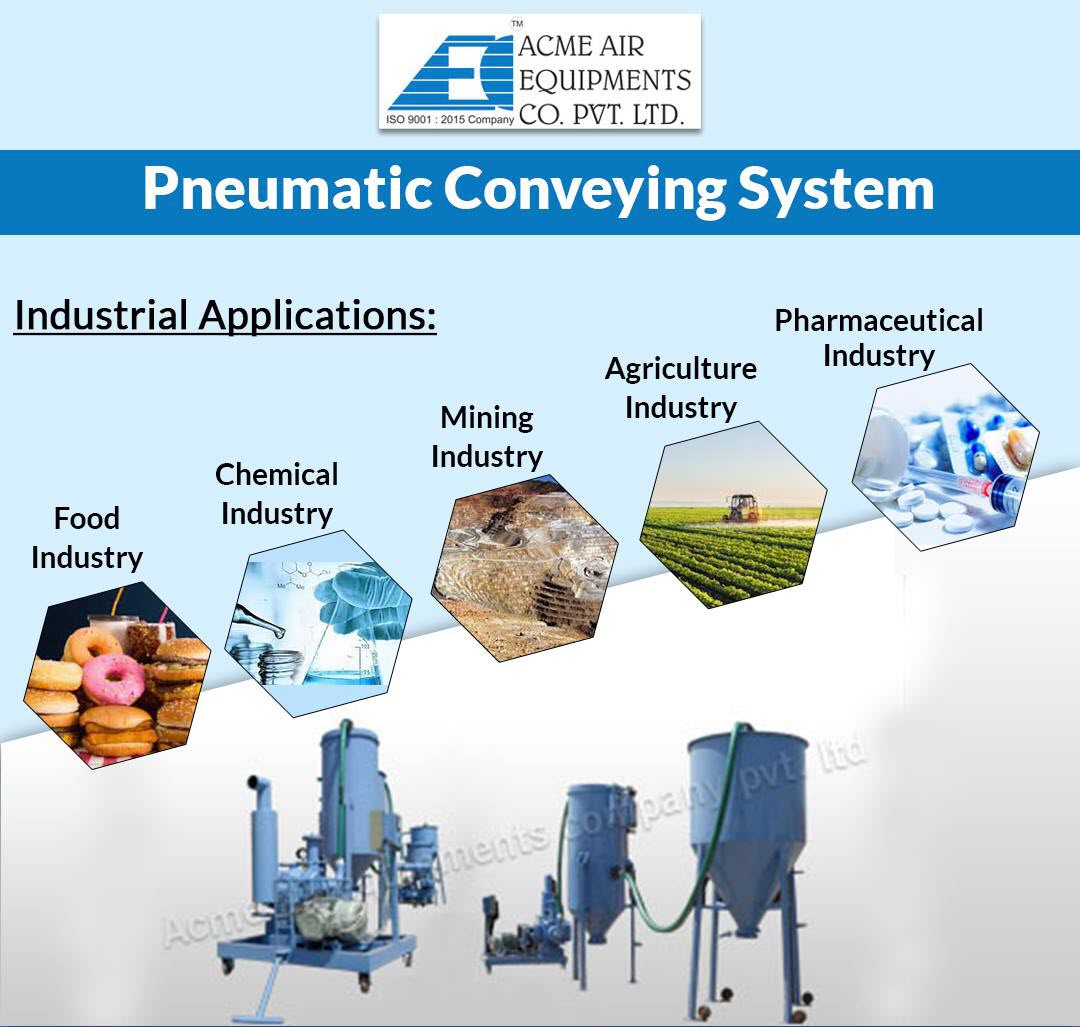

Applications of Pneumatic Conveying Systems

Pneumatic Conveyor Applications in Various Industries

Pneumatic conveying systems have a wide range of applications across different industries. In the food processing industry, these systems are used to transport ingredients such as flour, sugar, and spices without contamination. In the pharmaceutical industry, pneumatic conveyors ensure the safe handling of powders and granules, maintaining product purity. The chemical industry uses these systems to convey raw materials and finished products, ensuring a clean and efficient transfer process.

Pneumatic Material Handling System in Manufacturing

In manufacturing, pneumatic material handling systems play a crucial role in maintaining product quality. These systems are used to transport raw materials, intermediate products, and finished goods within the production facility. By using pneumatic conveyors, manufacturers can minimise the risk of contamination and ensure a consistent and reliable material handling process.

Benefits of Pneumatic Conveying Systems

Contamination-Free Transport

One of the primary benefits of pneumatic conveying systems is their ability to provide contamination-free transport. Since the materials are enclosed within a sealed pipeline, there is no exposure to external contaminants. This is particularly important in industries such as food processing and pharmaceuticals, where product purity is essential.

Reduced Material Degradation

Pneumatic conveying systems, especially dense phase systems, are designed to handle materials gently, reducing the risk of material degradation. This is crucial for maintaining the quality of fragile or sensitive products during transport.

Flexibility and Versatility

Pneumatic conveying systems are highly flexible and can be customised to meet the specific needs of different applications. They can handle a wide variety of materials, including powders, granules, and pellets, and can be configured to transport materials over long distances or through complex routing systems.

Choosing the Right Pneumatic Conveying System Manufacturer

Factors to Consider

When selecting a pneumatic conveying system manufacturer, it is essential to consider factors such as the manufacturer’s experience, reputation, and the quality of their products. A reliable manufacturer will offer customised solutions tailored to the specific needs of your application and provide ongoing support and maintenance services.

Leading Pneumatic Conveying System Manufacturers

Several leading manufacturers specialise in pneumatic conveying systems, offering a range of products and services to meet the needs of different industries. These manufacturers are known for their innovative solutions, high-quality products, and excellent customer service.

Installation and Maintenance of Pneumatic Conveying Systems

Proper Installation

Proper installation is critical to the performance and longevity of a pneumatic conveying system. It involves ensuring that the system is correctly configured, all components are securely connected, and the system is thoroughly tested before operation. Working with an experienced pneumatic conveying system manufacturer can ensure a smooth and successful installation process.

Regular Maintenance

Regular maintenance is essential to keep the pneumatic conveying system operating at peak efficiency. This includes routine inspections, cleaning, and replacing worn or damaged components. A well-maintained system not only performs better but also has a longer lifespan, reducing the need for frequent replacements and associated costs.

Improving Product Quality through Pneumatic Conveying Systems

Ensuring Consistent Product Quality

By providing contamination-free transport and reducing material degradation, pneumatic conveying systems help ensure consistent product quality. This is particularly important in industries where even minor contamination or material damage can lead to significant product defects.

Enhancing Operational Efficiency

Pneumatic conveying systems also enhance operational efficiency by providing a reliable and consistent material handling process. This reduces downtime, minimises the risk of product defects, and improves overall productivity.

Supporting Sustainable Practices

Pneumatic conveying systems support sustainable practices by reducing waste and minimising energy consumption. By ensuring efficient and contamination-free transport, these systems help industries meet their sustainability goals and reduce their environmental impact.

Future Trends in Pneumatic Conveying Systems

Advancements in Technology

The future of pneumatic conveying systems lies in advancements in technology. Innovations such as smart sensors, automated controls, and advanced materials are being developed to enhance the performance, efficiency, and reliability of these systems. Staying updated with these advancements allows industries to adopt cutting-edge solutions that improve product quality and operational efficiency.

Integration with Smart Manufacturing

Integrating pneumatic conveying systems with smart manufacturing technologies is becoming increasingly popular. This integration allows for real-time monitoring and control of the conveying process, enabling predictive maintenance, optimising performance, and reducing downtime. Smart manufacturing technologies also provide valuable data and insights that can be used to further improve the efficiency and reliability of pneumatic conveying systems.

Conclusion

Pneumatic conveying systems play a vital role in improving product quality by providing contamination-free transport and reducing material degradation. These systems are essential in industries such as food processing, pharmaceuticals, and manufacturing, where product purity and quality are critical. By selecting the right pneumatic conveying system manufacturer, ensuring proper installation and maintenance, and staying updated with advancements in technology, industries can leverage the benefits of pneumatic conveying systems to enhance product quality and operational efficiency.

1. What is a pneumatic conveyor and how does it work?

A pneumatic conveyor uses air pressure or vacuum to transport bulk materials through pipelines, ensuring contamination-free material handling across various industries.

2. What are the different types of pneumatic conveying systems?

There are two main types: dense phase, which transports materials at low velocities and high pressure, and lean phase, which operates at high velocities and low pressure.

3. What industries benefit from pneumatic conveying systems?

Industries such as food processing, pharmaceuticals, chemicals, and manufacturing benefit by using these systems for contamination-free and efficient material transport.

4. How do pneumatic conveying systems enhance product quality?

By ensuring contamination-free transport and reducing material degradation, these systems maintain the integrity and quality of products, which is crucial in sensitive industries.

5. What should be considered when choosing a pneumatic conveying system manufacturer?

Consider factors like the manufacturer's experience, reputation, product quality, and ability to provide customized solutions and ongoing support.

6. Why is regular maintenance important for pneumatic conveying systems?

Regular maintenance, including inspections, cleaning, and component replacement, ensures peak efficiency, reduces downtime, and extends the system's lifespan.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.

Table of Contents

Roots Blower | Positive Displacement Blower | Twin Lobe Blowers | Tri Lobe Blowers | Gas Boosters | Cement Feeding System | Dust Collector System | Catalyst Loading / Unloading Systems | Pneumatic Conveyor | Mechanical Vacuum Boosters | Vacuum Pumps | Liquid Ring Vacuum Pump | Water Ring Vacuum Pump | Two Stage Vacuum Pump | Oil Sealed Vacuum Pump | Big Bag Unloading System | Turbo Blower

© 2024 Acme Air Equipments | All Rights Reserved - SEO, GEO & Google Ads by Opal Infotech