The Liquid Ring Vacuum Pump is a type of positive displacement rotating pump. This type of liquid vacuum pump is used for a variety of vacuum applications. The main difference between a ring and a piston pump is their design. A cylinder is usually used in conjunction with a rotary vane vacuum pump. This makes a ring-type ring pump very popular. Nevertheless, a ring-type nozzle is not as common as a syringe-type liquid syringe.

Basic Principle of Liquid Ring Vacuum Pump

The basic principle of a liquid ring vacuum pump is to use a compatible fluid such as water, mineral oil, or organic solvents. Besides this, the liquid can also be already in the process. The operating fluids are continuously supplied to the compression stage and discharged together with the gas or condensate. This explains the liquid ring vacuum pump working principle, and why they are employed in so many different sectors. Hence, a liquid ring pump is an excellent choice for certain applications. If you are unsure of which type of ring vacuum pump is right for your specific requirements, we have some tips for you.

Different Advantages of Liquid Ring Vacuum Pump

The Liquid Ring Vacuum Pump is a versatile device, capable of producing high vacuums in a wide variety of applications. The liquid ring acts as a piston, compressing gases and releasing them through the discharge port. A liquid ring is placed between two impeller blades, and as the pump rotates, it draws the gas into a small space between the blades. This ring is used to remove air or other gas. The main advantage of a rotary valve is that it has multiple functions. This makes it a flexible solution for a vacuum system. In addition to the rotary valve, the pump also includes the rotor.

How to Choose Liquid Ring Vacuum Pump?

Even though the Liquid Ring Vacuum Pump is one of the most commonly used types of rotary vane pumps, it is necessary to choose the correct one for your needs. If you don’t know what to look for in a vacuum pump, you should take measurements before purchasing. Ensure that the pressure of the liquid ring is sufficient for your specific application and also know oil vacuum pump working principle. This will ensure that the vacuum is maintained at all times.

These pumps are designed to last for many years and offer a high vacuum level. When selecting a liquid ring vacuum pump, you need to choose the one that meets your needs. It is essential to select a model that is compatible with your needs. Once you have made your selection, you can begin looking for a replacement for the pump.

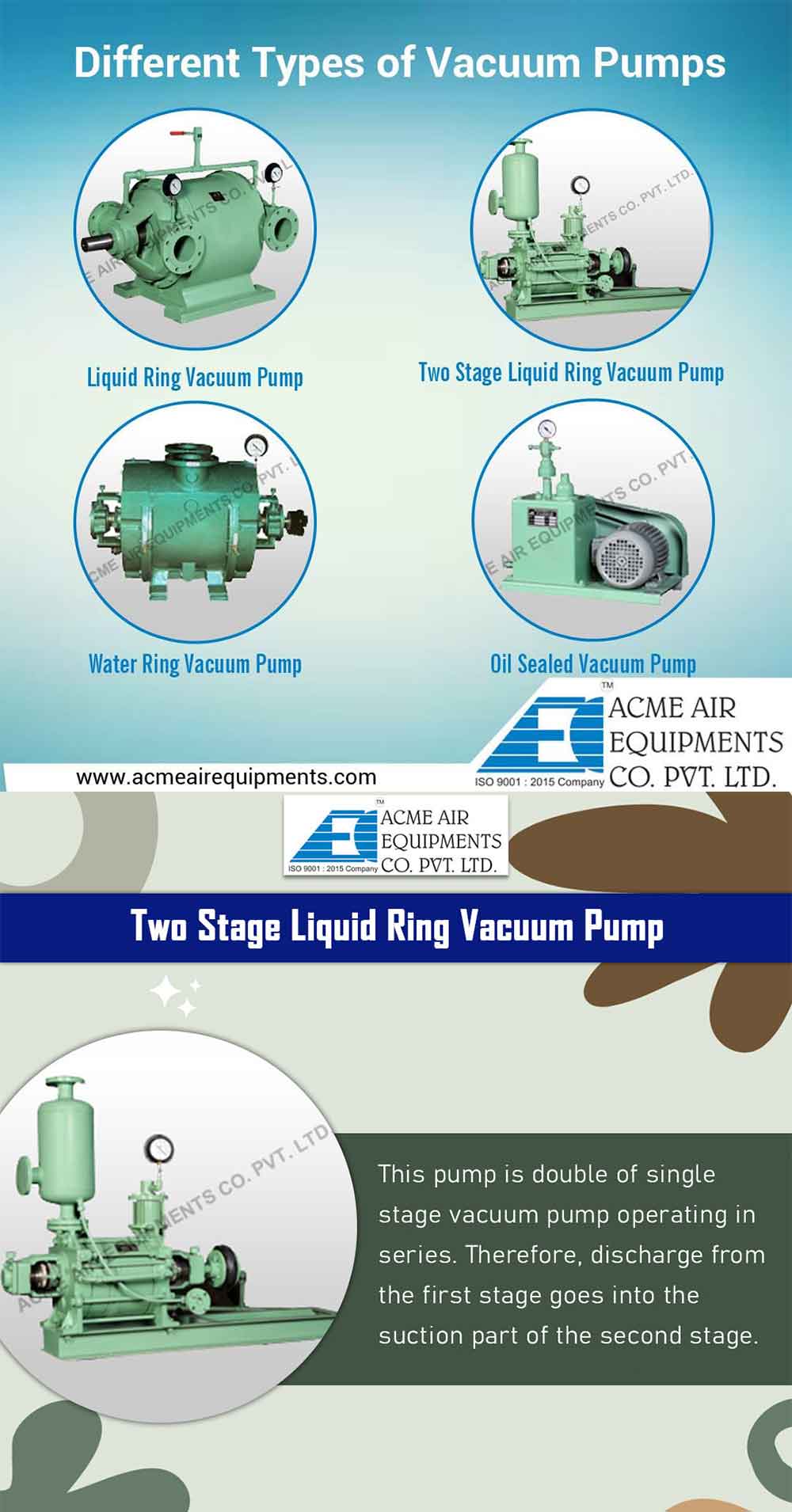

Two-Stage Liquid Ring Vacuum Pump

The Two-Stage Liquid Ring Vacuum pump is a proven solution for process vacuum applications. And Acme Air Equipments has been providing high-quality double stage vacuum pumps systems, and single stage vacuum pumps for decades and has a reputation for reliability. The two-stage design offers maximum efficiency and is suitable for a variety of industrial environments.

Features and Design of Two-Stage Liquid Ring Vacuum Pump

The design of the pump’s impeller has two stages to distribute the vapor pressure of the sealant. In addition to that, the pumps have a variety of sizes to suit different needs. The liquid ring vacuum pump is available in the highest quality.

The double-stage liquid ring vacuum pump has a higher capacity than the single-stage water ring pump. It has a wide range of working pressures than the single-stage water ring vacuum pump. In addition, it is more efficient in a wide range of pumping rates. And while these pumps are expensive, they are worth the price.

Several Benefits of Two-Stage Liquid Ring Vacuum Pump

The double-stage liquid ring vacuum pump has high maximum pressure. Unlike single-stage water ring vacuum pumps, two-stage liquid ring pumps offer better efficiency. They are more effective at higher vacuum levels and can also be used in chemical and pharmaceutical installations. These products are available for a wide range of applications.

Its compact design, reduced power consumption, and variable discharge port make it ideal for continuous operation. Designed for pharmaceutical and chemical installations, the two-stage pump has lower exhaust pressure and greater efficiency than its single-stage counterpart. So, if you need a deep vacuum, this is a great solution. These machines have the highest level of efficiency and are ideal for most industrial environments.

The Bottom Line

The two-stage pump has many advantages. It is ideal for vacuum applications in a deep vacuum, such as cheese processing, evaporation, sterilization, or extrusion venting. Its compact design and mechanical seals make it suitable for any industrial application. In addition to its energy efficiency, the two-stage water ring pump can provide a high-quality discharge port. This makes it a versatile solution for a variety of industrial settings. The efficiency of the Two-Stage Liquid Ring Vacuum is higher than that of the Single Stage Liquid-Ring Vacuum Pump. So, it is a perfect choice for various applications.