In the industrial landscape of India, where efficiency and innovation are paramount, pneumatic conveying systems have become an integral part of various manufacturing processes. These systems play a crucial role in moving bulk materials within a factory or plant. In this article, we’ll explore the world of pneumatic conveying systems and shed light on some of the prominent manufacturers in India.

Pneumatic conveying systems have revolutionized the way industries handle materials like powders, granules, and other bulk substances. They provide a seamless and efficient method for transporting these materials from one point to another, all while minimizing manual labor and enhancing productivity.

What is a Pneumatic Conveying System?

A pneumatic conveying system is a mechanism that uses air or gas flow to transfer bulk materials through a pipeline. This technology has gained immense popularity due to its ability to transport a wide range of materials, including cement, flour, plastic granules, and more.

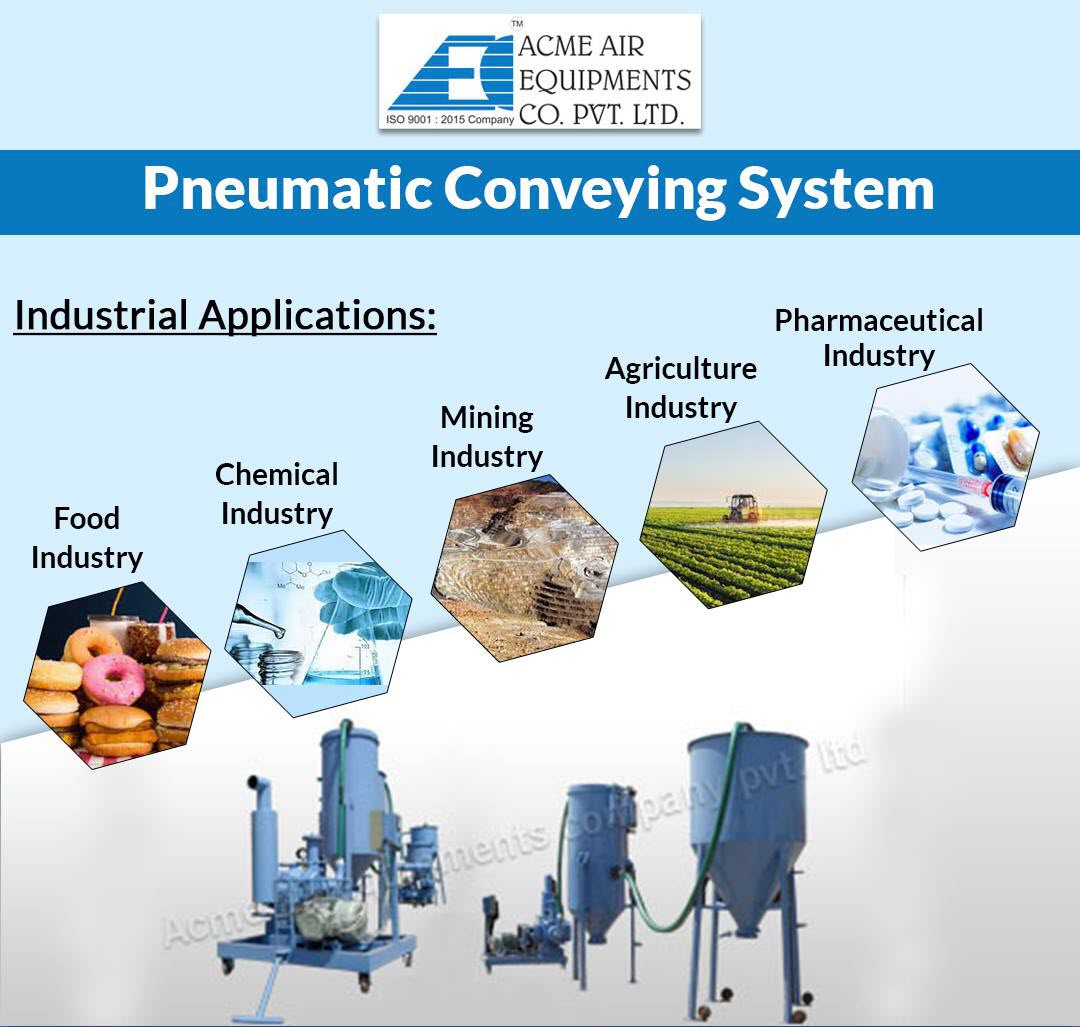

Applications of Pneumatic Conveying Systems

These systems find application in a multitude of industries, including food processing, pharmaceuticals, agriculture, and construction. Whether it’s transferring grains from a silo to a processing unit or moving cement to a construction site, pneumatic conveying systems offer a versatile solution.

Key Components of Pneumatic Conveying Systems

Pneumatic conveying systems comprise several essential components, such as air compressors, pipelines, filters, and material receivers. Each part plays a vital role in ensuring the smooth and efficient flow of materials.

Types of Pneumatic Conveying Systems

Dilute Phase Pneumatic Conveying

Dilute phase conveying involves suspending materials in a high-velocity air stream. This method is suitable for lighter materials like powders and granules.

Dense Phase Pneumatic Conveying

Dense phase conveying, on the other hand, utilizes lower air velocities to move heavier materials like cement and minerals. This method is known for minimizing material degradation.

Advantages of Pneumatic Conveying Systems

Pneumatic conveying systems offer numerous advantages, including:

- Reduced material wastage

- Dust-free operation

- Minimal manual handling

- Energy efficiency

Factors to Consider When Choosing a Manufacturer

Selecting the right pneumatic conveying system manufacturer is a critical decision. To make an informed choice, consider the following factors:

Customization Options

Ensure the manufacturer can design a system that aligns with your unique requirements and materials.

Quality and Efficiency

Quality and efficiency go hand in hand. Look for a manufacturer known for both high-quality components and efficient systems.

Maintenance and Support

After-sales service is vital. A manufacturer that offers maintenance and support can ensure your system remains in optimal condition.

Cost-Effectiveness

While budget constraints are a reality, it’s essential to balance cost with the quality and features of the system.

Pneumatic Conveying System Manufacturers across India’s Top Cities

India’s industrial ecosystem is rich with innovation and efficiency, and the pneumatic conveying system industry has played a vital role in supporting the growth of various sectors. Across the country, several cities have emerged as hubs for the manufacturing, export, and supply of these advanced systems. Here’s a closer look at how pneumatic conveying system manufacturers are shaping industries across some of India’s top cities.

Pneumatic Conveying System Industry in Northern India

- Pneumatic Conveyor in Delhi NCR

As one of the largest industrial hubs in the country, Delhi NCR hosts a diverse range of pneumatic conveying system manufacturers. These companies cater to a variety of industries, including food processing, construction, and pharmaceuticals. Their proximity to key transport and trade routes ensures timely delivery of products to clients both within India and overseas. - Pneumatic Conveyor in Ludhiana

Known for its engineering expertise, Ludhiana’s manufacturers specialize in high-quality pneumatic conveying systems tailored to industries like agriculture and textiles. These systems are designed to handle materials like grains, seeds, and powders efficiently, contributing to the city’s prominence as a leading industrial hub.

Western India’s Role in Pneumatic Conveying Systems

- Pneumatic Conveyor System in Mumbai

Mumbai, the financial capital of India, is home to numerous exporters and suppliers of pneumatic conveying systems. Many manufacturers in this region focus on creating systems for the chemical, pharmaceutical, and construction sectors. Mumbai’s strategic location also makes it a gateway for international trade, enhancing its significance in the pneumatic conveying market. - Pneumatic Conveying System in Ahmedabad

Ahmedabad has established itself as a key player in the pneumatic conveying industry, thanks to its strong presence in the manufacturing sector. The city’s manufacturers excel in providing customized solutions for industries like cement, plastics, and food processing. These systems are known for their energy efficiency and adherence to international quality standards. - Pneumatic Conveyor in Pune

Pune’s vibrant industrial landscape has attracted several manufacturers of pneumatic conveying systems. Known for their innovation, Pune-based companies often integrate advanced technologies such as IoT and automation into their systems. These solutions are widely used in automotive, pharmaceutical, and agricultural industries.

Southern India: A Thriving Hub for Pneumatic Conveying Systems

- Pneumatic Conveying System in Bangalore

Bangalore, the Silicon Valley of India, is not only a leader in technology but also a growing hub for pneumatic conveying systems. The city’s manufacturers leverage cutting-edge technologies to design systems that meet the needs of the electronics, food processing, and aerospace industries. Their focus on research and development ensures high-quality and future-ready systems. - Pneumatic Conveying Systems in Chennai

Chennai is renowned for its engineering prowess, making it a prominent center for pneumatic conveying system manufacturing. Manufacturers in this city cater to industries like cement, mining, and pharmaceuticals. Their systems are known for their robustness and ability to handle heavy-duty applications with precision. - Pneumatic Conveyor in Hyderabad

Hyderabad, often referred to as India’s pharmaceutical capital, is a key supplier of pneumatic conveying systems tailored to pharmaceutical and food industries. The city’s manufacturers emphasize compliance with stringent hygiene standards, ensuring the safe handling of sensitive materials.

Eastern and Central India’s Contribution

- Pneumatic Conveyor Systems in Kolkata

Kolkata, with its long-standing industrial legacy, is home to manufacturers specializing in pneumatic conveying systems for industries like jute, cement, and agriculture. The city’s strategic location near ports facilitates easy export of these systems to international markets. - Pneumatic Conveyor in Nagpur

Nagpur, located at the heart of India, plays a crucial role in supplying pneumatic conveying systems to industries across the country. Its manufacturers focus on energy-efficient systems for applications in power plants, mining, and fertilizers, ensuring reliable material handling solutions for these demanding sectors.

Why Regional Presence Matters for Pneumatic Conveying Systems

Each of these cities contributes uniquely to India’s pneumatic conveying system market, driven by the industrial strengths of the region. Having manufacturers spread across the country ensures better access to localized support, reduced delivery timelines, and systems designed to meet the specific needs of industries in that region.

Emerging Trends in Pneumatic Conveyor Manufacturing across Indian Cities

- Technological Integration

Cities like Pune and Bangalore are leading the way in adopting smart technologies like IoT, automation, and AI for pneumatic conveying systems. These advancements help optimize system performance and reduce operational costs. - Focus on Sustainability

From Ahmedabad to Chennai, manufacturers are working on eco-friendly designs that reduce energy consumption and material wastage, aligning with global sustainability goals. - Export Growth

Mumbai and Kolkata-based exporters are expanding their reach to international markets, driving demand for systems that meet global quality standards.

Factors Driving the Growth of Pneumatic Conveying Systems in Indian Cities

- Diverse Industrial Base: The presence of a wide range of industries in cities like Mumbai, Hyderabad, and Ludhiana ensures consistent demand for pneumatic conveying systems.

- Infrastructure Development: Cities like Chennai and Ahmedabad benefit from well-established industrial parks and logistic networks, enabling manufacturers to scale their operations.

- Government Initiatives: Initiatives like “Make in India” and infrastructure investment in Tier-2 and Tier-3 cities further boost the growth of this sector.

Future Trends in Pneumatic Conveying Systems

As technology continues to evolve, pneumatic conveying systems are likely to become even more efficient and environmentally friendly. Manufacturers will focus on developing systems that reduce energy consumption and environmental impact.

Conclusion

In India, pneumatic conveying systems have transformed the way industries handle bulk materials. They offer efficiency, reliability, and cost-effectiveness. When considering pneumatic conveying system manufacturers, choose a partner that can tailor solutions to your specific needs, ensuring the success of your operations.

The pneumatic conveying system industry is thriving across India’s top industrial cities. From Delhi NCR to Nagpur, manufacturers are not only meeting the domestic demand but also positioning India as a global hub for innovative and efficient material handling solutions. Businesses seeking reliable systems can leverage the regional expertise of these manufacturers, ensuring optimal solutions tailored to their unique needs.

By recognizing the strengths of these cities, industries can partner with manufacturers who understand the specific requirements of their region, ensuring efficient and cost-effective material handling processes.

Frequently Asked Questions About Pneumatic Conveying System

Pneumatic conveying systems can transport a wide range of materials, including powders, granules, cement, flour, and even sensitive pharmaceutical ingredients.

Pneumatic conveying systems find applications in various industries, including food processing, pharmaceuticals, agriculture, construction, and more.

Consider factors such as customization options, quality, maintenance, and cost-effectiveness when selecting a manufacturer.

Yes, many manufacturers offer customization options to tailor systems to the unique requirements of each client.

The future of pneumatic conveying systems lies in increased efficiency and reduced environmental impact, with a focus on energy-saving technology and sustainability.