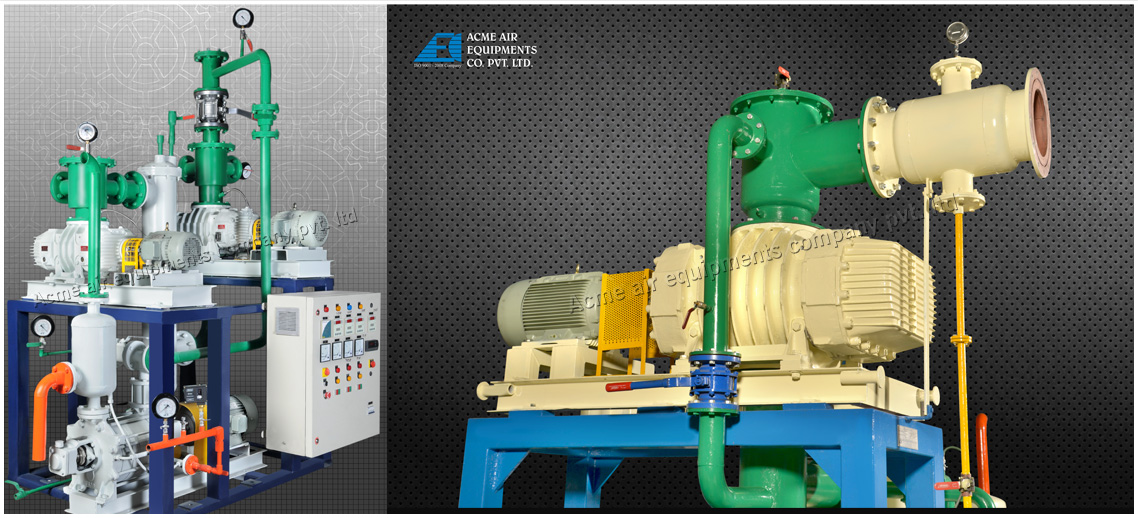

Mechanical Vacuum Boosters (Booster Compressor)

Acme Air Equipments Company Pvt. Ltd. is an ISO 9001-2015 Company. We design and manufacture premium quality Mechanical Vacuum Boosters as well as complete Vacuum Booster System in our State-of-the-art modern manufacturing facility. This is an ideal vacuum systems for re-used oil distillation.

The design and construction of vacuum booster compressor involves two counter rotating impellers with a special contour. These vacuum compressors rotate with a very finite and sharp clearance and without any physical contact. Variance in design offers Twin or Tri lobe Booster in air cooled or water cooled execution. The Vacuum Boosters are designed to handle vapors and gases at lower specific power consumption. They offer precise and constant volume displacement at rated condition.

The integration of the system is accomplished by utilizingTwo Stage liquid ring pump/Oil sealed Vacuum Pump/ Rotary Dry Vacuum pump/Reciprocating Pump/Steam or Water Jet Ejector as primary pump.

Some of the common applications are Distillation, Degassing, Coating, Refining of industrial Oil, Vacuum Impregnation, Semi conductor Processing, Separation of fluids, Space simulation, Vacuum freeze drying.

Frequently Asked Questions – Mechanical Vacuum Boosters

The purpose of Mechanical Vacuum Boosters is to enhance the performance of vacuum systems by increasing the volume displacement of vapors and gases at lower specific power consumption.

A Vacuum Booster Compressor consists of two counter-rotating impellers with a special contour that rotate without any physical contact. They are designed to provide precise and constant volume displacement at rated conditions.

Mechanical Vacuum Boosters find applications in various industries such as distillation, degassing, coating, refining of industrial oil, vacuum impregnation, semiconductor processing and separation of fluids, space simulation, and vacuum freeze drying. They are commonly used for the used oil distillation process.

The complete Vacuum Booster System consists of a core Booster connected to other equipment like a primary pump, condensers, filters, valves, drive, and instrumentation. It functions in the desired mode to cover a wide spectrum of vacuum levels, ranging from 10 to 10⁻³ mbar. A backing pump, watering pump, or oil seal pump is used to generate the initial vacuum.