In the world of industrial processes, efficient movement of air and gases is essential for a wide range of applications. Roots blowers, also known as positive displacement blowers, play a pivotal role in facilitating this crucial movement. This article delves into the significance of roots blowers in various industries, their working principle, and their contribution to efficient processes.

Introduction

Industrial processes rely on the seamless movement of air and gases to facilitate operations ranging from wastewater treatment to material handling. Roots blowers stand as essential components that drive this movement efficiently and effectively.

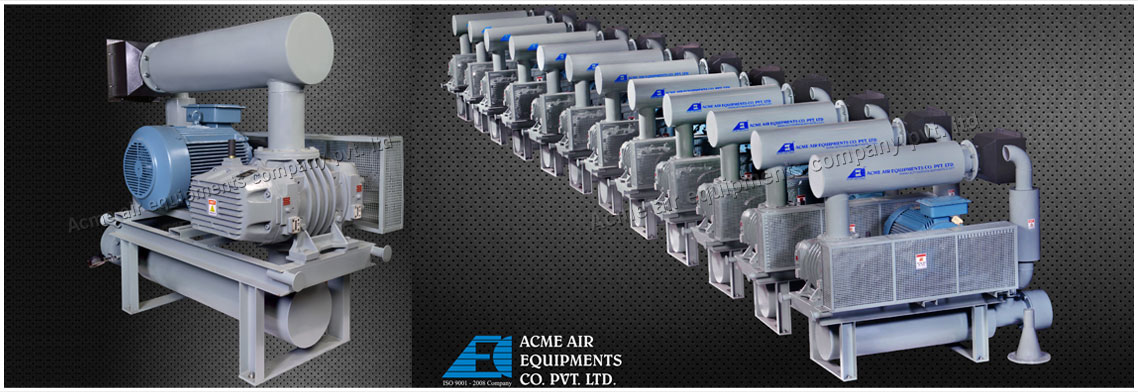

Roots Blowers: A Brief Overview

Understanding Positive Displacement

Roots blowers belong to the category of positive displacement machines. Unlike dynamic machines that rely on velocity to move air, positive displacement machines use fixed chambers to trap and transport air or gases.

The Roots Blower Design

Roots blowers are characterized by their distinctive design, comprising two rotors that rotate in opposite directions within a housing. These rotors have lobes that intermesh without touching, creating chambers that trap and move air or gas.

The Working Principle of Roots Blowers

Air Intake and Compression

As the rotors rotate, air is drawn into the space between the lobes and the housing. This trapped air is then compressed as the rotors continue to rotate, leading to a buildup of pressure within the chambers.

Discharge and Continuous Cycle

Once the air reaches a certain pressure, it is discharged through an outlet port. The rotors’ continuous rotation ensures a steady and consistent flow of air or gas, making roots blowers suitable for various industrial applications.

Applications of Roots Blowers in Industry

Wastewater Treatment

Roots blowers are crucial in aeration systems for wastewater treatment. They introduce oxygen into the treatment process, promoting the growth of aerobic microorganisms that break down organic matter.

Pneumatic Conveying

In pneumatic conveying systems, roots blowers transport bulk materials through pipelines using air or gas. This application is common in industries such as agriculture, chemical, and manufacturing.

Chemical and Petrochemical Processes

Roots blowers facilitate the movement of gases in chemical and petrochemical processes. They aid in processes like gas circulation, vacuum creation, and vapor recovery.

Food and Beverage Manufacturing

In the food and beverage industry, roots blowers are used for processes like drying, cooling, and packaging. Their ability to provide a controlled flow of air or gas is crucial in maintaining product quality.

Benefits of Roots Blowers

High Efficiency

Roots blowers offer high efficiency due to their positive displacement design. They deliver a consistent flow of air or gas regardless of changes in pressure, ensuring reliable performance.

Reliability and Durability

Roots blowers are known for their robust construction, making them durable even in challenging industrial environments. Their simple design minimizes the risk of mechanical failures.

Low Maintenance

The uncomplicated design of roots blowers translates to minimal maintenance requirements. This results in reduced downtime and operational disruptions.

Tailoring Roots Blowers to Specific Needs

Customization for Unique Processes

Industries often require roots blowers to be customized to meet specific process requirements. Modifications can include adjustments in rotor size, speed, and materials.

Variability in Blower Size and Power

Roots blowers are available in a range of sizes and power capacities. This flexibility allows industries to select blowers that align with their processing demands.

Environmental Considerations and Energy Efficiency

Roots Blowers and Sustainability

Sustainability is a growing concern in industrial processes. Roots blowers are being designed with eco-friendly considerations to minimize energy consumption and environmental impact.

Advancements in Energy-Efficient Designs

Innovations in roots blower design are focused on enhancing energy efficiency. Variable frequency drives (VFDs) and advanced control systems optimize blower performance and energy usage.

Challenges and Innovations

Noise Reduction

Roots blowers can produce noise during operation. Efforts are being made to reduce noise levels through improved design, materials, and noise-dampening technologies.

Enhancing Efficiency and Performance

Ongoing innovations aim to enhance the efficiency and performance of roots blowers. Computational fluid dynamics (CFD) and advanced materials contribute to optimized designs.

Future Prospects of Roots Blowers

Integration with Industry 4.0

As industries embrace Industry 4.0 technologies, roots blowers are likely to be integrated into smart systems for remote monitoring, predictive maintenance, and process optimization.

Continued Technological Advancements

The future holds promise for further technological advancements in roots blower design. These advancements will contribute to increased efficiency, reduced environmental impact, and enhanced performance.

Conclusion

Roots blowers serve as unsung heroes in various industrial processes, ensuring the smooth and efficient movement of air and gases. With their simple yet effective design, roots blowers play a vital role in industries ranging from wastewater treatment to manufacturing. As industries evolve and demand for efficiency and sustainability increases, roots blowers will continue to adapt and innovate, driving progress across sectors and enhancing industrial operations on a global scale.