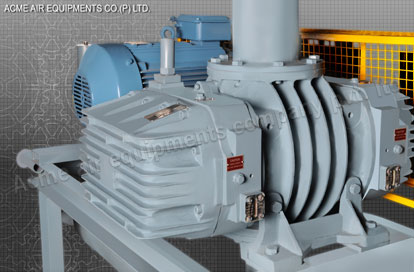

The rotary compressor is a popular piece of equipment that produces compressed air. It can be classified as either an oil-flooded or a liquid-ring rotary. Both types can be used for various industrial purposes. You can also buy a smaller rotary compressor for small industrial use. Its size and compact design make it ideal for many applications.

Features of Rotary Compressor

A rotary compressor has three moving parts: a blade, a roller and an eccentrically mounted roller that are arranged in a closed chamber. These three components work together to increase the pressure of a low-pressure gas into a high-pressure gas. The oil injected into the rotors reduces the temperature of the compressed air and serves as a hydraulic seal. The air enters the compressor on the “suction side” of the air-end, where it passes through the rotors. Once the air exits the compressor, it goes through a separation process. The oil is then routed back into the system, while the air is discharged.

Oil-sealed rotary compressors are used for a variety of industrial applications. In addition to powering pneumatic tools, they are also used in gas refrigeration and hydrocarbon processing. This type of compressor is ideal for industries with a high volume of air that fluctuates throughout the day.

The rotary compressor has two types: reciprocating and rotary. The reciprocating compressor is used in smaller applications like retail and home improvement, while the rotary screw air compressor is used in large industrial applications. These machines use up to 900 horsepower. The most common type of rotary compressor is the helical twin screw type, which has two mated rotors that trap air. Typically, a rotary compressor is available in both lubricated and oil-free versions. A rotary compressor has three main parts: an oil separator, a motor drive, and a rotor.

Advantages of Rotary Compressor

A rotary compressor has more advantages than disadvantages. A rotary compressor can run continuously, while a reciprocating compressor must operate at a minimum 60 percent duty cycle. A rotary screw is also quieter than a reciprocating compressor. It also produces cooler air that is easier to dry. But a rotary screw is not the most efficient option for most air applications.

The power consumption of a rotary compressor varies with the load and unload conditions. The way the compressor is controlled can determine the energy efficiency of the air system and the performance of the compressor. One of the simplest control strategies is a start/stop strategy, which means the motor drives the compressor in response to a pressure switch. This strategy is most appropriate for smaller compressors with less than 30 horsepower.

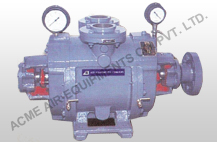

Liquid Ring Rotary Air Compressor

A liquid ring rotary air compressor is a good choice for many industrial applications because it offers high efficiency and reliability. They can be constructed from different materials. They are also available as single-stage and multi-stage compressors. Some of the benefits of a liquid ring compressor include its low initial costs and high reliability.

The liquid ring pump’s operating principle is quite simple. The rotor is driven by an induction motor and is eccentrically mounted inside the casing. The liquid is then fed into the compressor, where the centrifugal force creates a moving liquid ring. The ring fills the space between the vanes of the impeller and forms a compression chamber.

Applications of Liquid Ring Rotary Air Compressor

Another advantage of a liquid ring compressor is that it pumps almost any gas, including flammable and explosive gases. This is because the liquid ring has no friction surface and can pump a variety of non-condensable and vapours. A common liquid used as the service liquid is water, but other liquids can be used as well. Besides being effective for a wide variety of applications, a liquid ring compressor also has a long-life cycle and reduces maintenance costs.

The liquid ring vacuum compressor is widely used in process industries for the recovery of vapors and gases. These units are designed to operate in harsh environments. They are also available with energy-efficient features and reduced sealing water consumption. The demand for liquid ring compressors is expected to grow at a rate of nearly five percent per year through 2029. In the refinery industry, liquid ring compressors are used for hydrogen and chlorine compression. They are also ideal for biodiesel production and transesterification processes.

Benefits of Liquid Ring Rotary Air Compressor

The liquid ring pump is an efficient alternative to conventional air compressors. It works by compressing a gas through an impeller rotating inside a cylindrical casing. In the process, a liquid (usually water) forms a moving ring against the interior wall of the casing and reduces the volume of the gaseous process medium. The liquid ring then discharges the compressed medium via a guide plate.

Liquid ring rotary air compressors also produce compressed air from high-pressure gas and liquid. They are designed to operate at high speeds while minimizing noise. Their synchronous operation eliminates the need for a gearbox device. Their low-friction design means they experience less wear and tear. They also operate well at partial loads.

The Bottom Line

The rotary compressor is a workhorse of the compressor industry. Designed to run continuously for many weeks a year, rotary compressors have the reliability and efficiency to last for a long time without overheating or deteriorating. This type of compressor can be used in a variety of applications ranging from industrial processes to home applications.