Table of Contents

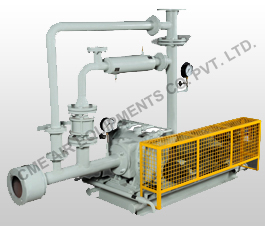

Know about Gas Boosters by reading the sections below. You’ll also learn about the different types of boosters, including hydraulics, electric motors, and low-pressure air. When it comes to buying these products, make sure to read the information in the product literature and follow the instructions carefully. This type of gas-boosting system doesn’t generate heat during the pumping process, which eliminates the need for oversized oil reservoirs or heat exchangers.

Why use Hydraulics in Gas Boosters?

In a gas booster, hydraulics is used to increase the pressure of the compressed gas. There are two types of hydraulic-driven gas boosters: single-stage and double-stage models. Single-stage boosters are used when maximum pressures are less than seven kW. Single-stage models are designed with a single power source and are available in either single or double-stage configurations. Two-stage models feature modular construction and can be operated simultaneously.

Why use Electric motors in Gas Boosters?

There are many different types of boosters, and each has its own pros and cons. These types of boosters may be powered by hydraulics, an electric motor, a manual lever system, or both. Each has its advantages and disadvantages. The power source is decided upon by the architect or designer who designed the system. Here are some common types and what they do. Read on to learn about these types of boosters, and how they can be used for your next project.

Benefits of Low-Pressure Air Gas Boosters

These low-pressure air gas boosters are used to increase the volume of compressed air to a specific level. They are powered by an electric motor, hydraulics, or low- or high-pressure air. Some are even driven by a lever system. In addition to these features, they may also include a pressure gauge and safety features such as a tamper-resistant lid. Below, we’ll review the most important features of a low-pressure air gas booster and provide some helpful tips for selecting one.

What is Manual Lever System in Gas Boosters?

A manual lever system for gas boosters is a mechanical device that combines a pump and a cylinder. The pump has a pressure gauge and a lever for regulating gas pressure.

What is a Single Stage Gas Booster?

A single-stage gas booster has a single cylinder with two gas-boosting sections. The cylinders are operated alternately, with the drive piston section operating continuously. A four-way air cycling valve and dual air pilot valves control the flow of gas through the booster. A single-stage gas booster’s pressure capabilities range differently, and its advantages include its portability and purity.

The Bottom Line

The global market for gas boosters is segmented according to the types, applications, and end users. This article offers recommendations for newcomers as well as existing players in the market of gas boosters. And, these suggestions are vital for gaining a competitive edge in the gas booster market.

About Author

CEO

Mr. Vishwesh Pardeshi is the CEO of Acme Air Equipments Company Pvt. Ltd., an industrial and engineering goods manufacturing company based in Ahmedabad, Gujarat (India). He has taken over the responsibility from founding Partners and Directors of the Company, and is now leading a talented group of professionals since 2020 by bringing in vast industrial and management expertise. By qualification, he holds a Bachelor Degree in Mechanical Engineering and also holds a MBA degree from reputed institutes. Under his leadership, the Company has successfully executed prestigious projects by delivering high quality and world class products from a state of the art manufacturing facility which combines CNC-enabled precision manufacturing and strong after sales support. In line with the Vision, Mission and Core Values of the Organization, Mr. Vishwesh Pardeshi continues to drive Quality, Reliability and Global Expansion at Acme Air Equipments Co. Pvt. Ltd.